The infrared thermal camera: Carer at the forefront of tests on electric trucks

During their operational use, forklifts face costly operations, which intensely stress their moving parts and components. For this reason, all the prototypes made by the Carer design departments are subjected to thermal tests with infrared cameras, in order to immediately discover any anomalies during handling activities. A further demonstration of the avant-garde achieved by the Carer production departments.

A sort of X-ray of the machine in operation: this is the most concise way to describe the test with infrared thermal camera to which Carer subjects all the prototypes of the electric trucks before their launch on the market. This is a fundamental step in the pre-production phase, which allows any anomalies to be identified and corrected before the trucks are subjected to their usual operational use, which greatly stresses their moving parts and components. Through very intense proof and inspection tests, it is verified that all the working parts respect the temperature parameters for which they were designed and the cooling systems are tested. All these indications allow to keep under control even those components that are not monitored by the standard detection systems already implemented on new machines.

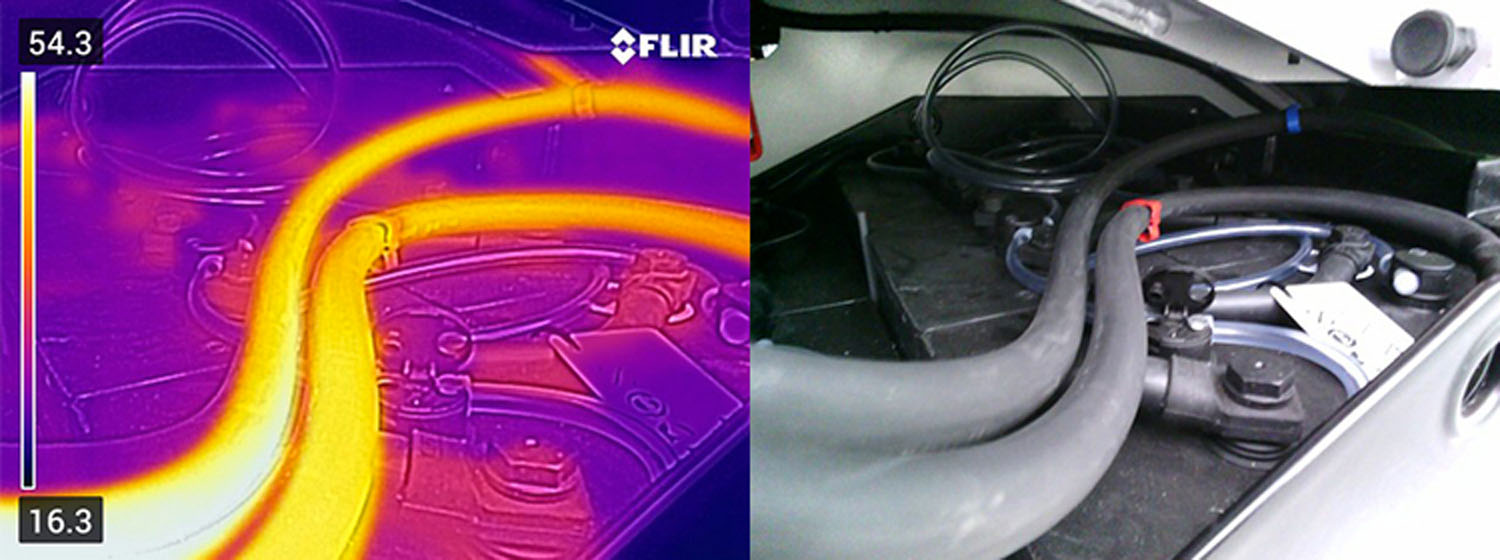

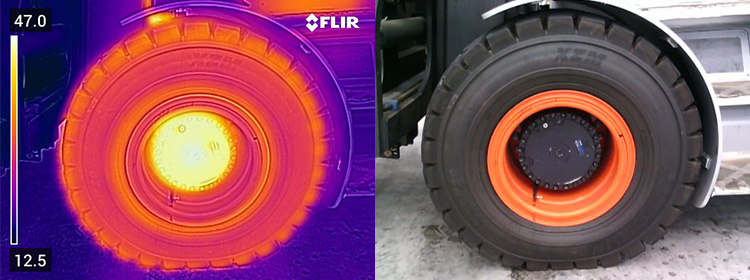

The infrared images of the thermal camera show the temperatures of the cables and batteries, of the cylinders involved in the hydraulic part (lifting, tilting), of the tires, of the front-wheel drive reducers (both of the mechanical and electrical parts) and of the components hydraulics outside the truck, while they are stressed by the operational applications.

The temperature range is indicated on the left side of the thermal photographs: at the bottom the coldest one, in violet-blue color, at the top the warmest one, in yellow-white color. This value is then recalculated based on the standard room temperature.

Through these tests it is possible to simulate all the operating and environmental conditions in which the trucks will operate, to establish whether all its components (from the electrical cables to the oil of the hydraulic circuits, from the cylinders to the gearboxes) remain within specifications of the product project and to discover any anomalies. When the thermal camera highlights unexpected hot spots, for example in the hub or in the tires, with temperatures that differ from the design parameters, we intervene to fix the anomaly and the prototype of the new truck is again subjected to new tests to fine-tune the ultimate machine.

The tests performed by Carer are performed according to the European standard (EN_16796) which specifies general test requirements and criteria to measure the energy consumption of self-propelled industrial trucks during their operation: for electric trucks, battery and battery charger efficiencies are also taken into consideration. A tool that allows at a glance to have a global view of the operation of the machine and to prevent any risks: for example, if a component overheats, even if it is not involved in particular functions, friction is discovered that should not occur.

The tests are then compared with field findings and allow Carer's engineers to settle the prototypes of the new trucks.

The use of tests with thermal cameras allows Carer to prevent malfunctions, anomalies due to overheating or damage to the trucks in different operating conditions and in the various applications of their actual use. Moreover, it constitutes a preventive detection system, which eliminates the risks of premature aging of the insulators due to the loss of efficiency of the lubricants following overheating. The parameters highlighted by the tests are also used to fine-tune the designs of new trucks.

For more information on thermal camera tests and on the Carer range of electric trucks, please contact us by calling 0039 0545.1938010 or writing to info@carerforklift.com.

Tags: Batteries, Indoor operations, Electric forklift trucks, Cables, material handling, handling operations, tires, hydraulic part , infrared cameras, thermal tests, prototypes, temperature parameters, cooling systems, standard detection systems, infrared images, cylinders, lifting, tilting, front-wheel drive reducers, components hydraulic, operating and environmental conditions, design parameters, European standard (EN_16796), battery charger, tests with thermal cameras , overheating